How Does a Sand and Dust Test Chamber Expose Potential Product Defects?

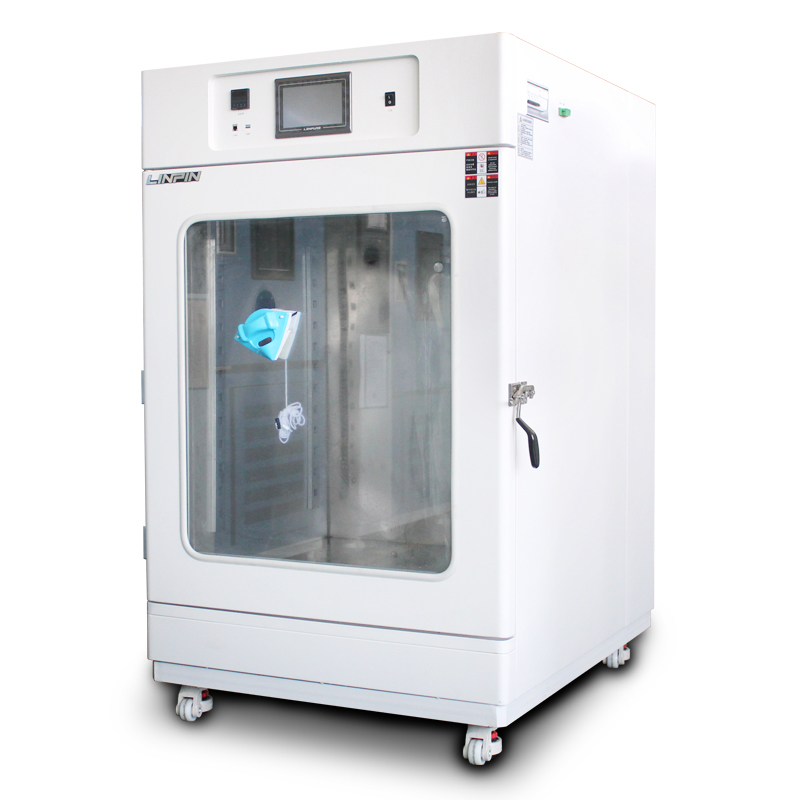

Author:LINPIN Update Time:2025-09-24 Source:LINPINIn modern industrial manufacturing, product reliability and durability are critical factors determining market competitiveness. As a vital environmental testing device, the sand and dust test chamber accurately exposes potential design and manufacturing flaws by simulating extreme sandy and dusty conditions, providing scientific data to enhance product quality.

Simulating Harsh Environments: Replicating Real-World Challenges

The sand and dust test chamber precisely controls parameters such as particle concentration, airflow velocity, temperature, and humidity to replicate harsh environments like deserts, mines, and construction sites. This testing not only evaluates the sealing performance of product enclosures but also assesses the resistance of internal components to dust ingress. For example, if dust penetrates electronic devices during testing, it may indicate inadequate gasket design or assembly flaws. Similarly, mechanical parts experiencing wear or jamming in sandy conditions reveal material or structural design weaknesses.

Multi-Dimensional Defect Exposure

- Sealing Defects: If gaps in product casings (e.g., seams, ports) fail to meet protection standards (such as IP ratings), dust can infiltrate and cause short circuits or sensor failures. The chamber identifies weak points through continuous dust spraying and negative pressure tests.

- Material Durability Issues: Certain materials may exhibit surface abrasion, corrosion, or aging under sand and dust exposure. Testing reveals problems like coating peeling or metal rust, guiding material optimization.

- Functional Failures: Moving parts like fans or bearings may accumulate particles, increasing operational resistance or causing complete failure. Test data directly reflects real-world performance adaptability.

- Design Flaws: Hard-to-clean areas or poorly designed ventilation structures can lead to dust buildup, overheating, or performance degradation. Test results provide actionable insights for design improvements.

Authoritative Testing and Value Realization

Sand and dust test chambers comply with international standards (e.g., IEC 60529, GB/T 4208), ensuring repeatable and comparable results. Early-stage testing helps companies avoid post-production recalls, reduce warranty costs, and strengthen brand credibility. Industries such as automotive components, military equipment, and outdoor communication devices rely on these tests to guarantee reliability in extreme conditions.

More than a quality inspection tool, the sand and dust test chamber drives innovation by rigorously exposing defects. It empowers businesses to enhance product resilience at the design stage, ultimately delivering high-quality solutions that withstand time and environmental challenges. Choosing scientific testing methods is choosing a future of user accountability.